The hidden cost of overmilking: why every second counts after milk flow stops - Part 2

Listen to this article!

In the previous article, we focused on the consequences of attempting to “get the last drop” of milk. Avoiding this is possible and advisable, thanks to the automated cluster removal technology. It addresses these issues through controlled, precisely timed detachment. Unlike manual systems dependent on operator judgment and availability, ACR technology ensures:

Optimal timing: clusters detach precisely when milk flow drops to predetermined thresholds, eliminating guesswork and reducing variation between milking sessions.

Safe detachment: vacuum equalization before cup removal eliminates shear forces and prevents sudden air admission that can drive contaminants into teat canals.

Consistent application: every cow receives identical treatment regardless of operator experience or workload pressure, ensuring standardized milking protocols across the entire herd.

Implementation strategies

For operations considering ACR implementation or seeking to optimize existing manual protocols, several key principles apply:

Critical timing parameters: research indicates that cluster removal should occur when milk flow drops to 0.2–0.5 kg/min, depending on the individual cow’s characteristics and stage of lactation. Such precision is virtually impossible to achieve consistently through manual observation alone.

However, in cows with a lactation yield above 9,000 liters, the detachment threshold should not be set below 0.5 kg/min. Lower values (0.2–0.5 kg/min) prolong the period of overmilking, increasing the risk of tissue damage and raising mastitis incidence. In practice, this means that parameters must be individually adjusted to herd productivity and lactation stage, rather than strictly following ranges reported in the literature.Vacuum management: maintaining appropriate system vacuum levels (typically 42-50 kPa) becomes even more critical when combined with proper timing protocols. Higher vacuum levels exacerbate tissue damage during any extended attachment period.

Pulsation optimization: ensuring adequate rest phases in pulsation cycles helps maintain tissue circulation and reduces congestion, providing additional protection against overmilking damage.

Measuring success

The benefits of eliminating overmilking are:

SCC reduction: well-implemented ACR systems typically show 10-20% reductions in bulk tank SCC within 3-6 months of installation.

Mastitis incidence: new infection rates often decline by 25-40% when proper timing and detachment protocols are consistently applied.

Teat condition scores: visual assessment of teat ends shows marked improvement in texture, color, and overall condition when overmilking is eliminated.

The economic reality

While the initial investment in ACR technology requires careful consideration, the economic benefits typically justify implementation costs within 18-24 months. Reduced treatment costs, improved milk quality premiums, and decreased labor requirements for cluster removal combine to create compelling financial returns.

Perhaps more importantly, the risk mitigation provided by consistent, gentle milking protocols protects against the catastrophic costs associated with chronic mastitis problems or sudden SCC spikes that can jeopardize milk marketing agreements.

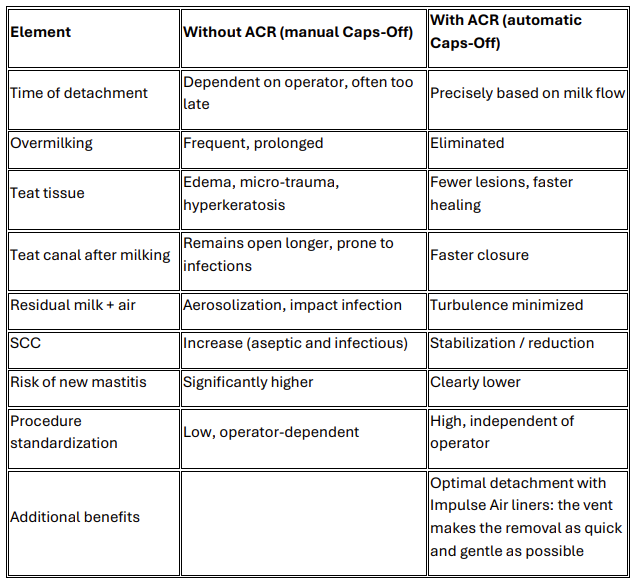

To sum up: without ACR vs. with ACR

Moving forward

The evidence is unambiguous: overmilking represents a preventable threat to udder health that compromises both animal welfare and operational profitability. Whether through ACR implementation or rigorously trained manual protocols, eliminating overmilking should be a priority for any operation serious about sustainable milk production.

The question isn't whether you can afford to address overmilking; it's whether you can afford not to. In an industry where margins are measured in pennies per hundredweight, protecting udder health through proper milking practices isn't just good animal husbandry, it's essential business practice.

Sources

Journal of Dairy Science Vol. 101(8)

milkrite | InterPuls internal training materials

National Mastitis Council Guidelines

Teat condition in dairy cows: Assessment, effects, and importance Mein

Udder health and milking management Hamann – IDF Bulletin 371